Work-in-process inventory

Work-in-process inventory is materials that have been partially completed through the production process. These items are typically located in the production area, though they could also be held to one side in a buffer storage area. The cost of work-in-process typically includes all of the raw material cost related to the final product, since raw materials are usually added at the beginning of the conversion process. Also, a portion of the direct labor cost and factory overhead will also be assigned to work-in-process; more of these costs will be added as part of the remaining manufacturing process.

It is time-consuming to calculate the amount of work-in-process inventory, determine the percentage of completion, and assign a cost to it, so it is standard practice in many companies to minimize the amount of work-in-process inventory just prior to the end of a reporting period.

Work-in-process is an asset, and so is aggregated into the inventory line item on the balance sheet (usually being the smallest of the three main inventory accounts, of which the others are raw materials and finished goods).

It is generally considered a manufacturing best practice to minimize the amount of work-in-process in the production area, since too much of it interferes with the process flow. Also, if work-in-process is allowed to pile up at one work center before being shifted to the next one, this means that a series of flawed units could build up before being discovered at the next work center. Further, production expediters may be used to force certain key jobs through the pile of work-in-process jobs, which throws the production system into an even greater muddle. Instead, work-in-process should move between work centers one unit at a time, with very little inventory piling up between workstations. Ideally, a lean production environment should contain so little work-in-process inventory that the amount on hand is immaterial.

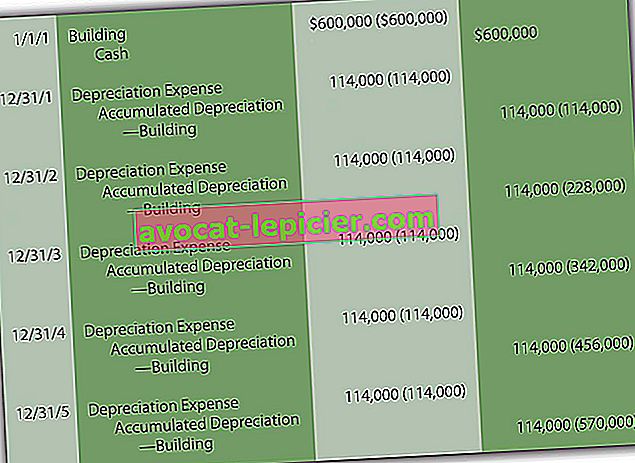

Work-in-process is a much more significant issue when it involves the construction of a building. In this case, work-in-process includes the accumulated cost of the asset, which will continue to increase until the structure is declared complete.

Related Terms

Work-in-process inventory is also called work-in-progress inventory or WIP inventory.